June 9, 2025

Written by

gopi

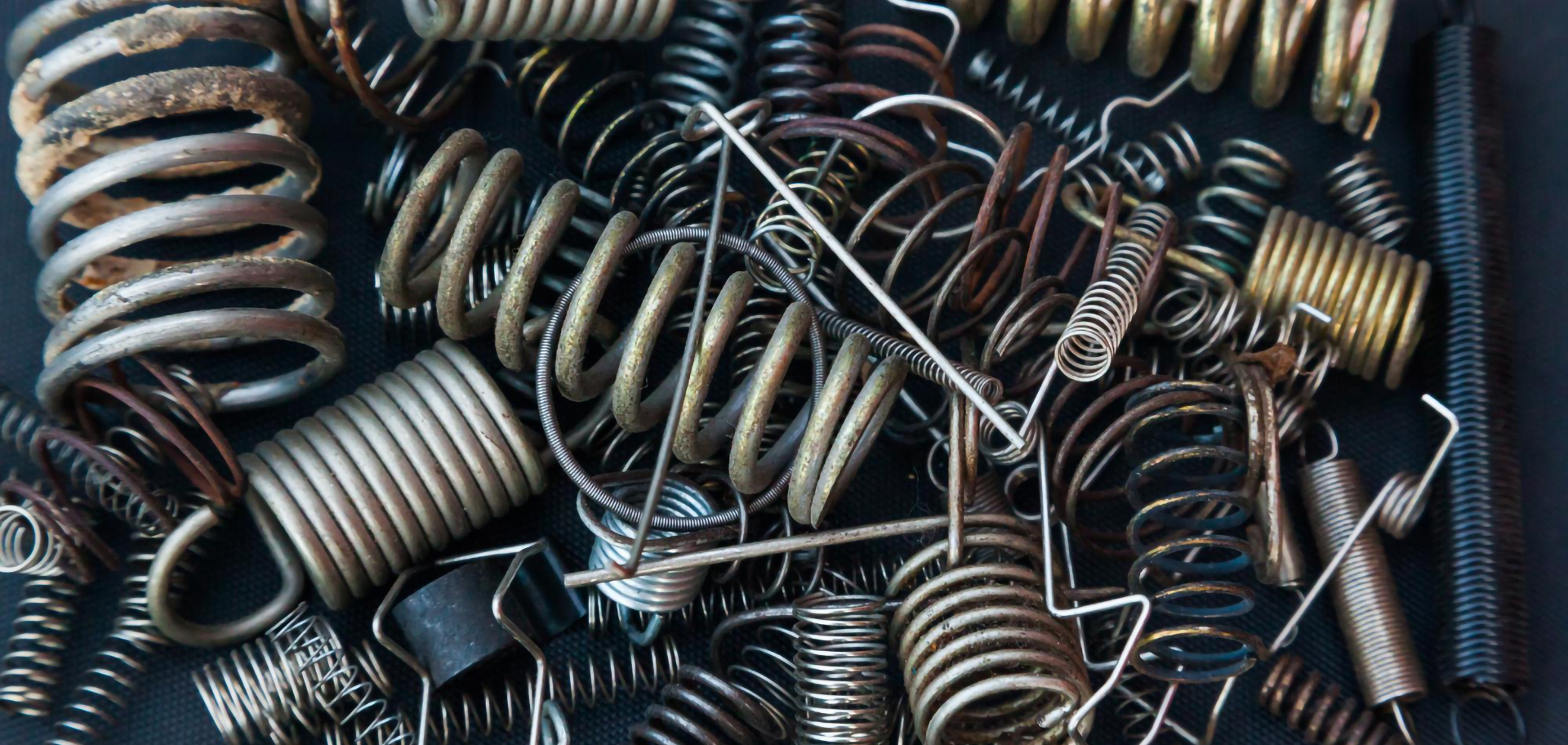

Metal stamping is a versatile and essential process in manufacturing, used to shape and form metal sheets into precise components for various industries. The success of metal stamping largely depends on the materials chosen for the process. Selecting the right material ensures optimal performance, cost-effectiveness, and longevity of the final product. This blog will explore the key factors to consider when selecting materials for metal stamping, guiding you through the decision-making process to achieve the best possible results for your project.

1. Understanding Material Properties

The first step in choosing the right material for metal stamping is understanding the properties of different metals. Each material offers unique characteristics that can significantly impact the stamping process and the performance of the final product. Key properties to consider include:

- Ductility: Ductility refers to a material’s ability to deform under tensile stress. Materials with high ductility, such as aluminum and copper, are ideal for complex shapes that require significant bending or drawing.

- Hardness: Hardness measures a material’s resistance to deformation, typically by indentation. Harder materials like stainless steel provide excellent durability and wear resistance but may be more challenging to stamp.

- Tensile Strength: This property indicates how much stress a material can withstand before breaking. High tensile strength materials, such as certain grades of steel, are suitable for components that will be subjected to heavy loads.

- Corrosion Resistance: If the final product will be exposed to harsh environments, selecting a material with strong corrosion resistance, such as stainless steel or galvanized steel, is crucial to ensuring longevity.

2. Considering the Application

The intended application of the stamped component plays a crucial role in material selection. Different applications require different material properties to meet specific functional requirements. For example:

- Automotive Industry: Components used in the automotive industry often require materials with high strength, wear resistance, and durability. Steel, especially high-strength low-alloy (HSLA) steel, is commonly used for its excellent mechanical properties.

- Electronics Industry: In the electronics industry, conductivity and corrosion resistance are critical. Copper and its alloys, such as brass, are often preferred for connectors, terminals, and other electrical components.

- Medical Industry: Medical devices and components require materials that are biocompatible and corrosion-resistant. Stainless steel and titanium are commonly used in this sector for their superior performance in medical applications.

3. Cost Considerations

While material performance is crucial, cost-effectiveness is equally important in the manufacturing process. Balancing material quality with cost can be challenging, but it is essential to ensure the economic viability of your project. Consider the following:

- Material Availability: Materials that are readily available in the market are generally more cost-effective. Specialized or rare materials may be more expensive due to limited supply.

- Processing Costs: Some materials require more complex processing techniques, which can increase production costs. For instance, harder materials may necessitate more advanced tooling or additional steps in the stamping process, leading to higher costs.

- Scrap Rate: Consider the material’s scrap rate during the stamping process. Materials that produce less waste and are easier to recycle can help reduce overall costs.

4. Material Compatibility with Stamping Techniques

Different stamping techniques, such as deep drawing, bending, or coining, require materials with specific characteristics. Ensure that the material you choose is compatible with the stamping method you plan to use. For instance:

- Deep Drawing: This technique involves pulling a sheet metal blank into a die to create a hollow shape. Materials with high ductility, like aluminum, are ideal for deep drawing as they can stretch without cracking.

- Bending: Bending involves deforming the metal along a straight axis. Materials with good formability, such as low-carbon steel, are suitable for bending processes.

- Coining: Coining is a precision stamping technique that creates intricate details on metal parts. Materials with high hardness and strength, like certain stainless steels, are often used for coining to achieve fine details without excessive wear on the tooling.

5. Environmental and Compliance Considerations

In today’s manufacturing environment, compliance with environmental regulations and industry standards is increasingly important. When selecting materials for metal stamping, consider the environmental impact and whether the material meets industry-specific regulations. For example:

- RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous materials in electrical and electronic equipment. Ensure that the materials you choose comply with RoHS regulations if your product will be sold in regions where these rules apply.

- Recyclability: Opting for materials that are easily recyclable can reduce the environmental impact of your manufacturing process. Metals like aluminum and steel are highly recyclable and can contribute to a more sustainable production cycle.

Conclusion

Choosing the right material for metal stamping is a critical decision that impacts the performance, cost, and durability of the final product. By understanding the material properties, considering the application, balancing cost-effectiveness, ensuring compatibility with stamping techniques, and adhering to environmental and compliance requirements, you can make informed decisions that lead to successful manufacturing outcomes. At Wireformers, Inc., we are committed to helping you select the best materials for your metal stamping projects, ensuring high-quality results that meet your exact specifications.