June 9, 2025

Written by

gopi

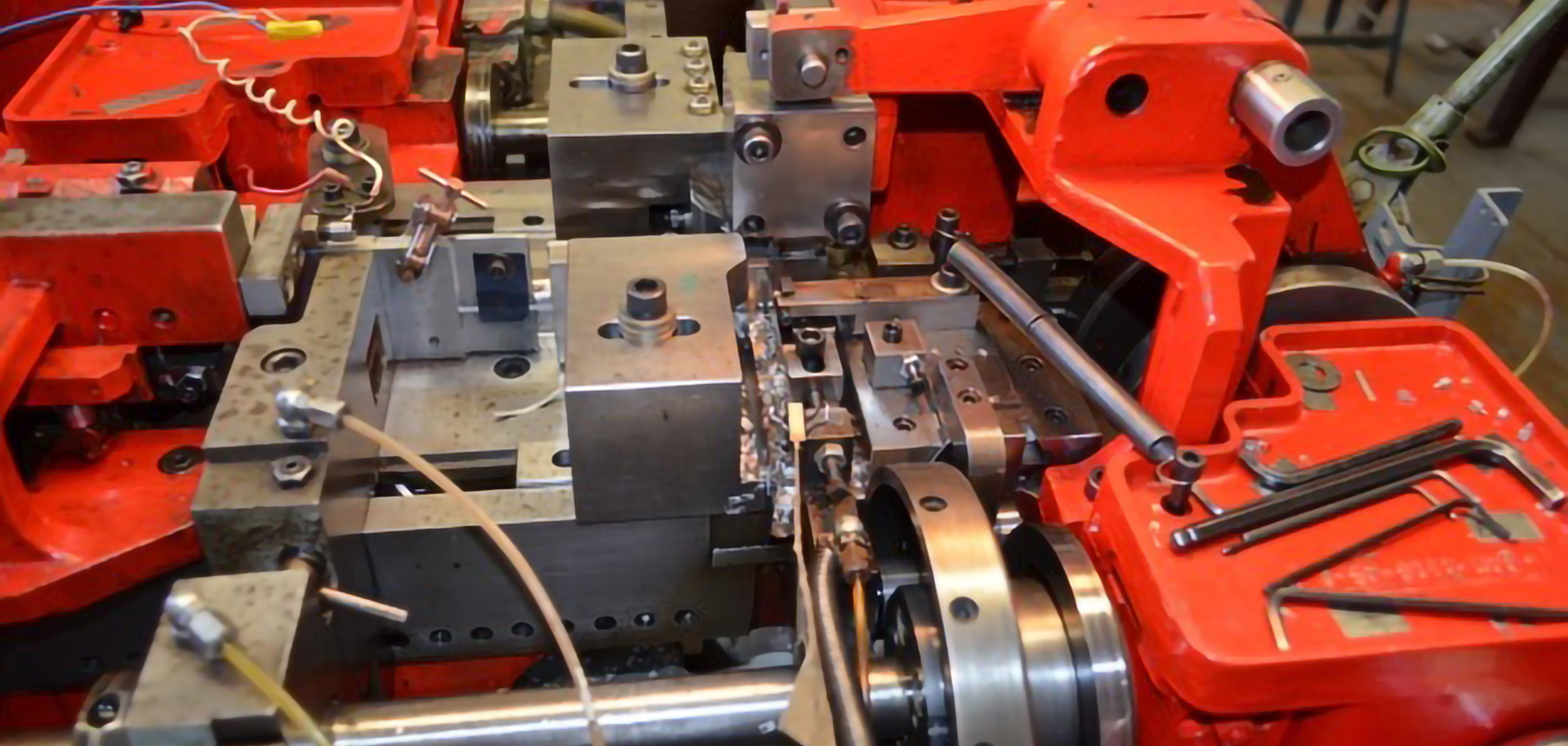

Fourslide machines, also known as multi-slide machines, are a vital component in the manufacturing industry, particularly when it comes to producing complex metal and wire parts. These machines offer a unique combination of precision, efficiency, and versatility that makes them an excellent choice for a wide range of applications. In this blog, we will explore the various benefits of using fourslide machines in manufacturing processes and why they are preferred over other traditional methods.

1. Precision in Complex Part Production

One of the most significant advantages of fourslide machines is their ability to produce highly complex parts with remarkable precision. Unlike traditional stamping or bending machines, which typically require multiple steps and setups to create intricate components, a fourslide machine can perform several operations simultaneously. This is made possible by the machine's design, which features multiple slides that move independently of each other, allowing for precise bending, cutting, and shaping of metal or wire.

The precision offered by fourslide machines is crucial in industries where exact specifications are required, such as automotive, electronics, and medical device manufacturing. Components produced by fourslide machines are consistent and meet tight tolerances, reducing the need for additional machining or finishing operations.

The precision offered by fourslide machines is crucial in industries where exact specifications are required, such as automotive, electronics, and medical device manufacturing. Components produced by fourslide machines are consistent and meet tight tolerances, reducing the need for additional machining or finishing operations.

2. Efficiency and Cost-Effectiveness

Fourslide machines are also known for their efficiency, particularly in high-volume production runs. Because these machines can perform multiple operations in one pass, they significantly reduce the time and labor required to produce complex parts. This efficiency translates into cost savings for manufacturers, as fewer machines, operators, and production steps are needed to achieve the desired results.

Moreover, the ability to produce intricate parts in a single process reduces material waste, further enhancing the cost-effectiveness of the production. The machine's design also allows for quick changeovers between different part designs, making it ideal for manufacturers who need to produce a variety of components without incurring long setup times.

Moreover, the ability to produce intricate parts in a single process reduces material waste, further enhancing the cost-effectiveness of the production. The machine's design also allows for quick changeovers between different part designs, making it ideal for manufacturers who need to produce a variety of components without incurring long setup times.

3. Versatility Across a Range of Applications

Another key benefit of fourslide machines is their versatility. These machines can work with various materials, including different types of metals and wire, and can produce a wide range of part sizes and shapes. Whether you need simple wire forms or complex stamped metal components, a fourslide machine can handle the task.

The versatility of fourslide machines makes them suitable for various industries, from automotive and aerospace to consumer electronics and medical devices. For example, in the automotive industry, fourslide machines are often used to produce small, intricate components such as clips, brackets, and connectors. In the medical device industry, they can be used to create precise, small-scale parts that meet stringent regulatory standards.

The versatility of fourslide machines makes them suitable for various industries, from automotive and aerospace to consumer electronics and medical devices. For example, in the automotive industry, fourslide machines are often used to produce small, intricate components such as clips, brackets, and connectors. In the medical device industry, they can be used to create precise, small-scale parts that meet stringent regulatory standards.

4. High-Speed Production

Speed is another critical factor where fourslide machines excel. These machines are designed for high-speed production, making them an excellent choice for manufacturers who need to produce large quantities of parts in a short amount of time. The multi-slide configuration allows for continuous operation, with each slide performing a specific operation in rapid succession. This capability not only increases throughput but also ensures that parts are produced consistently and with minimal downtime.

5. Reduced Tooling Costs

Compared to traditional stamping and bending machines, fourslide machines often require less complex tooling. The machine's design allows for the use of simpler, less expensive tools, which can be easily modified or replaced as needed. This not only reduces the initial tooling costs but also makes it easier and more cost-effective to produce different parts using the same machine.

Additionally, the reduced tooling complexity translates into faster setup times, further enhancing the machine's efficiency and flexibility. For manufacturers, this means they can quickly adapt to changing production needs without incurring significant additional costs.

Additionally, the reduced tooling complexity translates into faster setup times, further enhancing the machine's efficiency and flexibility. For manufacturers, this means they can quickly adapt to changing production needs without incurring significant additional costs.

6. Improved Design Flexibility

The design flexibility offered by fourslide machines is another significant advantage. These machines allow manufacturers to create complex shapes and geometries that would be difficult or impossible to produce with traditional stamping or bending methods. This flexibility opens up new possibilities for product design and innovation, enabling manufacturers to meet the evolving needs of their customers.

For example, fourslide machines can produce parts with multiple bends, twists, and curves, all in a single operation. This capability is particularly valuable in industries where space constraints or specific functional requirements demand intricate part designs.

For example, fourslide machines can produce parts with multiple bends, twists, and curves, all in a single operation. This capability is particularly valuable in industries where space constraints or specific functional requirements demand intricate part designs.

7. Environmental Benefits

In addition to their operational advantages, fourslide machines offer environmental benefits. The efficiency of these machines results in less energy consumption and reduced material waste compared to traditional manufacturing methods. This makes fourslide machines an environmentally friendly choice for manufacturers looking to minimize their environmental impact while maintaining high production standards.

Conclusion

Fourslide machines are a powerful tool in the manufacturing industry, offering a unique combination of precision, efficiency, versatility, and cost-effectiveness. Their ability to produce complex parts with high accuracy and speed makes them an ideal choice for a wide range of applications across various industries. Whether you're manufacturing components for the automotive, electronics, or medical device sectors, fourslide machines provide the reliability and performance needed to meet the most demanding production requirements.